|

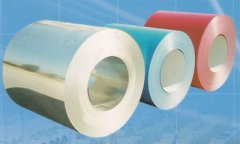

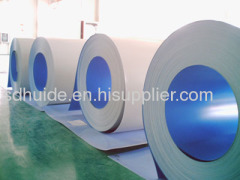

Shandong Boxing Huide Iron And Steel Co., Ltd.

|

Gold Index: 35368

special pre-painted steel coils

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

HD201134

Production Capacity:

200,000TONS/YEAR

Brand Name:

HUIDE

coating:

you decided

thickness:

0.135-1.0mm

weight:

3-9T

Means of Transport:

Ocean

Packing:

sea- worthy package

coating structureZ:

/2,2/1,1/1

Color:

RAL k7

inner core:

508-610mm

width:

800-1500mm

quality control,

best service ,

nice anti-corrosion

colors as per RAL k7

packing ,commerial package

Color-coated plates is in cold-rolled steel sheet and galvanized steel for basical plate , through the surface pretreatment (skimmed, cleaning, chemical conversion processing),in the method of continuous coated (roller coating method), then baked and cooling .

Common two coating ans two baking type ,consecutive color coating process .main product process is: open-book - pretreatment - coated - baking - post-processing - winding.

Product use:

Coating steel has advantages, beautiful and good anti-corrosion performance, and can be directly processed, it gives construction, shipbuilding, vehicle manufacturing, furniture industry, electric industries provides a new raw material and played by steel and wood, efficient construction, energy saving, prevent pollution and good effect.

Use of galvanized steel for substrate color-coated plates, except a zinc protection outside, zinc plane organic coating covered up, can prevent isolation effect, service life is steel rusty galvanized steel plate, according to introducing coating longer service life of galvanized steel long than 50%.

Color-coated plates applications:

Construction (outdoor) workshop, agricultural warehouse, house prefabricated components, corrugated roofs and walls, drainage, balcony railing, newsagent there, cold storage, goods sales pavilion, doors

Construction (indoor door, doorcase, housing light steel structure, screen, ceiling, elevator, stair, ventilation

Electrical appliances refrigerators, washing machines, switchgear, instrument ark, air conditioning, microwave oven, bread machine

Furniture radiators, chimney, chest, tables, beds, the more suitcase, bookshelf

Transportation cars and trains interior decoration, clapboard, container, ships diaphragms

Other for writing board, dustbin, billboards, clocks, typewriter, dashboard, weight implement, photographic equipment

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pre Painted Steel

Pre Painted Galvanized Steel

Pre Painted Steel Coil

Painted Steel Coils

Pre Painted Coil

Pre Painted Aluminum Coil

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Shandong Boxing Huide Iron And Steel Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company, Agent

City: Binzhou

Province/State: Shandong

Country/Region: China (Mainland)

You May Like:

Product (477)

- Encryption Products (1)

-

PPGI

(208)

-

GI

(71)

-

corrugated steel sheet

(103)

-

Sandwich Panels

(51)

- strip steel (10)

- c/Z/PURLIN (8)

- Others (25)